Materials and Construction

Knife on blanks made from recycled sawblade

Making knives has been my main occupation for over 25 years. My goal is to make long lasting, functional cutting tools -- knives that work well, feel right and look good.

One of the joys of being a craftsman (and living simply) as opposed to being a businessman worried about the "bottom line", is being able to slow down and enjoy the work. I find working with my hands and making something useful to be deeply satisfying.

Blades

Shaping blades helps me understand why "keep-

ing your nose to the grindstone" is a metaphor for

intense concentration as well as hard work.

I also use high carbon steel, either 0.1 or L.6, which I recycle from lumber mill sawblades. High carbon steel is easier to sharpen and holds a very good edge. It will, however, rust if left wet and acids in foods will etch patterns in the blade and darken it over time.

For knives that will be used around salt water I definitely recommend 440C; otherwise the choice is largely a matter of personal preference. Other steels -- for example, ATS34, 154CM, and D2 -- can be special ordered.

I grind custom blades freehand on a belt grinder to a satin finish, then send out for professional heat treating.

Most of my knives are full tang construction. Buried tang construction allows more scope in design and use of materials, and is almost as strong.

Kitchen knives are ground as thin as practical to minimize resistance in cutting and for ease of resharpening. Where fitted, bolsters, in brass or nickel silver, are silver soldered.

Handles

Shaping the handles is the fun part. I do it by

hand so that I can slow down and focus on feel

and balance.

Handles are epoxied to the tang and set with pins, cutler's rivets or bolts, then sanded to a fine finish and sealed with several applications of tung oil.

I select woods as much on the basis of their durability and texture as their grain pattern. Usually I have available various rosewoods, bubinga, padauk, yew and walnut. Other woods, as well as bone, horn and other exotic materials, can be special ordered.

I prefer the look and feel of natural wood. It does, however, require taking care of. A synthetic wood-resin laminate called dymondwood makes a very stable, moisture resistant handle and is available in a variety of bright colors.

Sheaths

Rigging knife sheath has a separate pocket

for the spike.

...and then there's the "magic" ingredient...

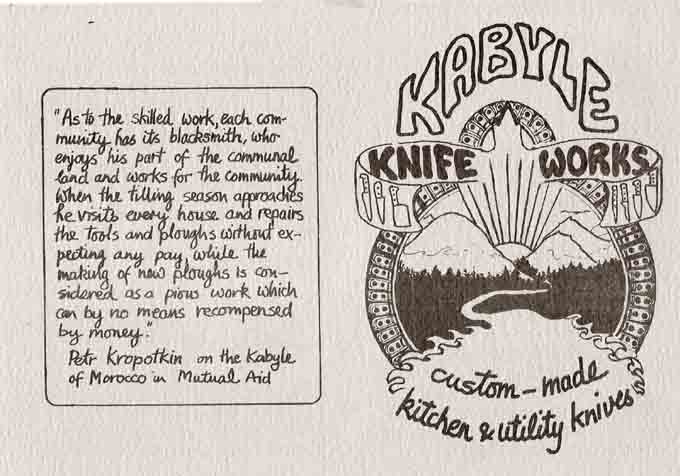

When I first started making knives, I called my enterprise Kabyle Knifeworks. The name came from a Moroccan tribe described in Petr Kropotkin's book Mutual Aid, which gives a different view of evolution from Darwin and his followers. Among the Kabyle, "the making of plows is considered pious work that can by no means be recompensed with money." The blacksmiths -- whose skills are vital-- did not think of cashing in on their talents; instead, they considered themselves blessed to have been chosen as a conduit through which the creative spirit is made manifest.

When the knife I am making is not just a commodity that I am marketing for profit, I slow down, I pay more attention, I become absorbed in the process; what the Buddhists call mindfulness whereby ordinary work is sanctified by the state of mind you bring to it. Work becomes a mixture of play and prayer, bringing me joy and fulfillment while at the same time infusing the knife with the energy needed for it to play its part in the alchemy of cooking, the transformation of food into nourishment of body and soul.

Guarantee:

With proper care my knives will give a lifetime of use. I will fix any failure due to faulty materials or poor workmanship.